Tepyrus

Advanced Short Cut Fiber

for Wet-Laid Nonwoven Applications

NEWS>

About TEPYRUS®

TEPYRUS® MAKES YOUR PRODUCTS BETTER

TEPYRUS is the trademark of TEIJIN FRONTIER's precision cut polyester fiber engineered for wet-laid nonwoven industry. TEPYRUS is one of the most reliable and versatile fiber sources commercially available in this field. Its' performance is backed by our continuing effort to respond to market needs. TEPYRUS is a dependable component that helps you make products better.

Features

Reliable

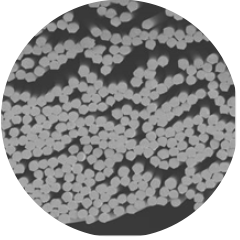

Precisely controlled production from chemical refinement through fiber cutting deliver superior dispersion. Reliable immediate dispersion delivers better processing efficiency and less waste.

Hybrid

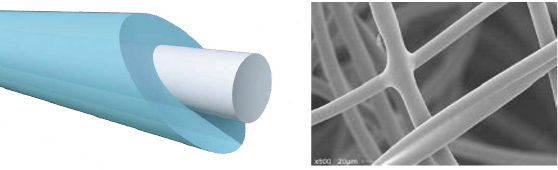

Bicomponent fibers encapsulate heat resistant structural fibers within low-melt point binding materials. Heat binding eliminates the need for chemical binders for inert applications and helps achieve superior performance.

Fineness

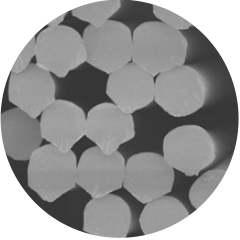

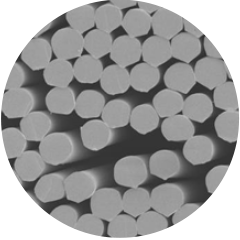

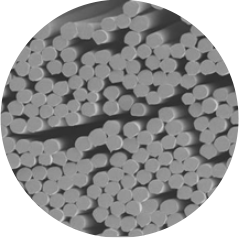

Low deviation of denier and fiber length compared with conventional short cut fibers. Diameter 2 μm at the finest with excellent uniformity of fiber cutting and dispersibility.

1.7 dtex : 12μm

0.6 dtex : 7μm

0.1 dtex : 3μm

0.06 dtex : 2μm

Variety

Available in a variety of fiber options : regular, crimped & flame retardant subject fibers, homo-polymer & bicomponent binders, recycled content & eco polymer alternatives. Solution based R&D starts from polymerization process to engineer customer fiber requirements to meet evolving market needs.

Applications

Industrial

Air Filter / Automotive Oil Filter

Reverse Osmosis Membrane

Electronics

Insulating Tape / Battery Separator

Medical

Surgical Tape / Surgical Gown

Surgical Mask / Transdermal Patch

Others

Tea Bag / Food Wrapper

Hygenic Wipe / Wall Liner

Specification

| Type | Decitex | Diameter(µm) | Length (mm) |

Characteristic |

|---|---|---|---|---|

| Super fine |

0.06 | 2 | 3 | |

| 0.1 0.3 |

3 5 |

3, 5 | ||

| Regular | 0.6 | 7 | 5, 10 | |

| 0.7 | 8 | 6H | High tenacity |

|

| 1.5 | 11 | 5H | High tenacity |

|

| 0.7 | 8 | 10 | High shrinkage |

|

| 1.7 | 12 | 5, 10, 15, 20 |

||

| 3.3 | 17 | 5, 10 | ||

| 8.0 | 27 | 5 | ||

| 2.2 6.6 |

14 24 |

5 | Crimped | |

| Flame retardant |

0.7 | 8 | 10 | High shrinkage |

| 1.7 | 12 | 5 | ||

| ECOPET®︎Ecological Meterails |

1.7 | 12 | 10 | |

| 2.2 | 14 | 5, 10 | Crimped trilobal |

|

| Homo-polymerBinder | 1.2 | 10 | 5 | Process temprature: 200℃~ |

| 1.2 | 10 | 5 | Process temprature: 180℃~ | |

| 0.2 | 4 | 3 | Process temprature: 150~200℃ | |

| Bi-componentBinder | 1.1 | 10 | 5 | PET/Co-PET (M. P. = 110℃) |

| 1.7 | 12 | |||

| 2.2 | 14 | |||

| 2.2 | 14 | 5 | PET/Co-PET (M. P. = 150℃) |

|

| 1.2 | 10 | 5 | PET/PE (M. P. = 135℃) |